| Availability: | |

|---|---|

GP-1000

EBP INSTRUMENTS

Shanghai, China

100 Sets Per Month

T/T

1 set

Product Feature:

1. Six pieces Φ30mm samples can be polished simultaneous

2. Single point pneumatic holding, no demo gripper

3. Multiple functions: one machine realizes the whole process of rough grinding, fine grinding, rough polishing and fine polishing of metallographic samples.

4. Single chip microcomputer control system, frequency converter speed control, the system is stable and reliable.

5. Grinding head with automatic / manual mode can be selected.

6. Three level constant speeds: customer can define three common speeds for pre-grinding, grinding and polishing

7. The automatic mode of grinding disc has eight sections of speed programming, which can set eight sections of speed and corresponding running time. Each section of speed can be automatically shut down at the corresponding time to facilitate users to replace sandpaper and polishing tissue.

8. Through the use of solenoid valve to control the water on and off, grinding disc under the automatic water spray cleaning device, can clean the inner wall of the sink.

9. Easily replace magnetic anti-stick disk, can complete all kinds of sample coarse, fine grinding and coarse, fine polishing processes, a plate is equivalent to N plates.

10. Beautiful outlook and good quality

Technical specification:

Model | GP-1000 |

Working disc diameter | φ254mm (option:φ230mm, φ203mm) With magnetic disk system |

Sample quantity | Standard 6 pieces of φ30 (or φ40 / φ50 three hole) |

Grinding disc speed | 100-1000 r/min; Support clockwise & anticlockwise rotate |

Three level constant speed | V1=300r/min V2=500r/min V3=800r/min; can set by needs at anytime |

Grinding head speed | 30-200r/min |

Sample holder | Standard φ30mm 6 pieces (Option: φ40-φ50mm 3 pieces,other size can be customized) |

Automatic mode | Can be programmed eight speed, running time and grinding wheel steering switch |

Working air source pressure range | ≥0.8MPa |

Sample pressure range | Suggestion:0.3-0.4MPa (recommend pressure >0.3MPa) |

Power supply | AC220V,50/60Hz |

Motor power | 0.75Kw |

Dimension | 700 x 730 x 350mm |

Weight | 74kg |

Standard accessories:

Item | Quantity | Item | Quantity |

Magnetic working plate(250mm) | 1piece | Anti-sticky disc(250mm) | 1peice |

Abrasive paper | 6 pieces | Polishing cloth | 2 pieces |

Waterproof ring | 1 piece | Water inlet pipe 8mm | 1 piece |

Water outlet pipe 25mm | 1 piece | Touch screen pen | 1 piece |

Anti-stick wheel | 1 piece | Magnetic wheel | 1 piece |

Power cord adapter (aviation plug connector) | 1 piece | Data cable (aviation plug) | 1 piece |

Rubber pad with filter | 1 piece | Triangle valve 4 | 1 piece |

Quick-connect coupling SNZ08-04 | 1 piece | Raw strip | 1 roll |

Hose clamp 21-44 | 1 piece | Filter mesh (# 60, double layer) | 4 pieces |

machine manual | 1 set | machine certification | 1 set |

Machine Guarantee card | 1 set | packing list | 1 set |

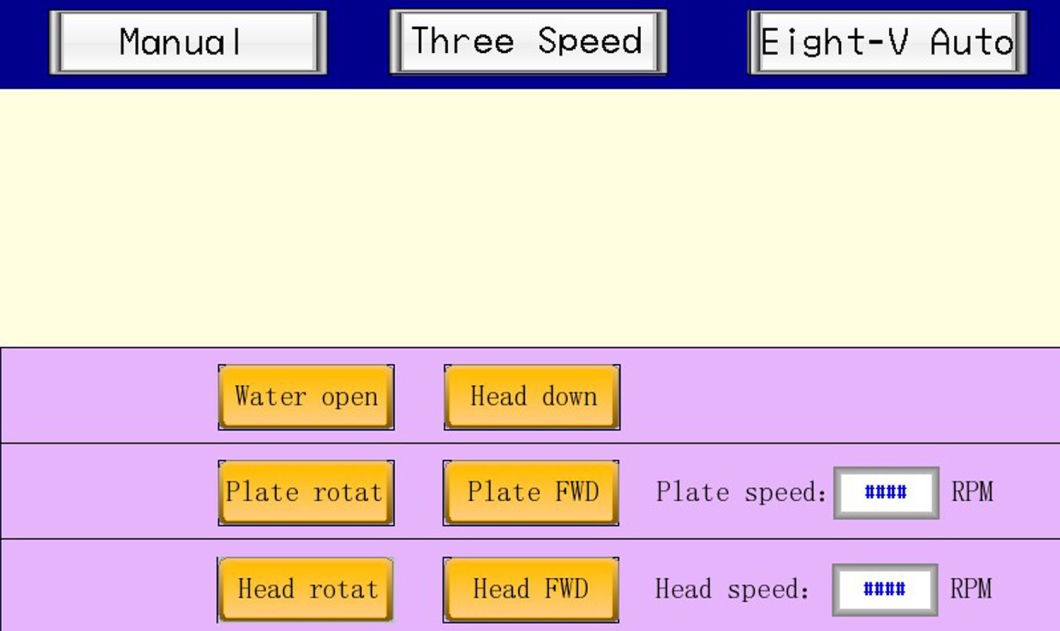

Main interface of 7'' Color touch screen:

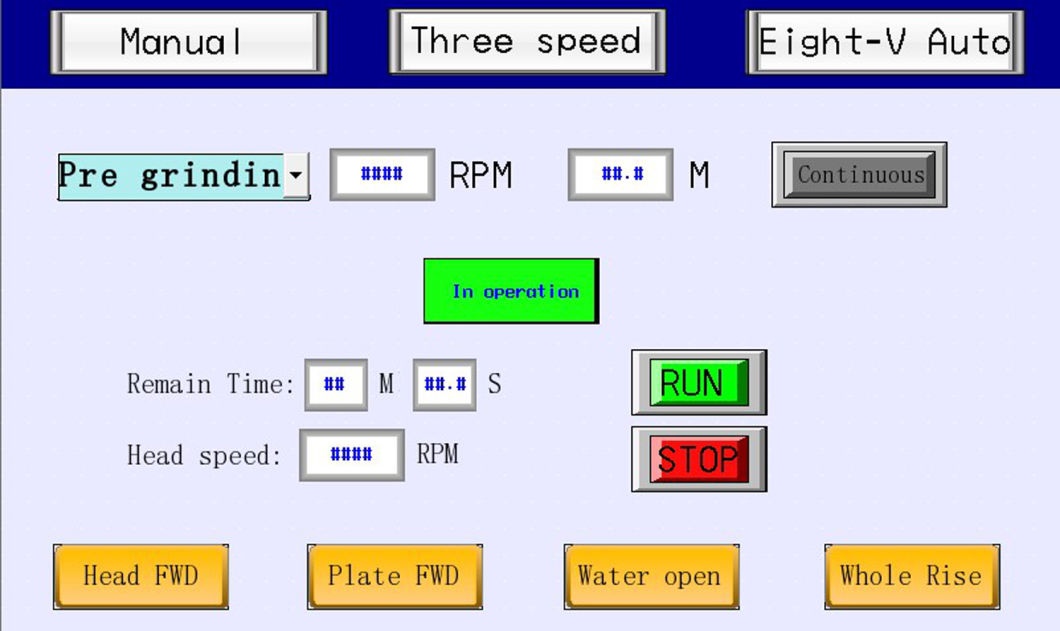

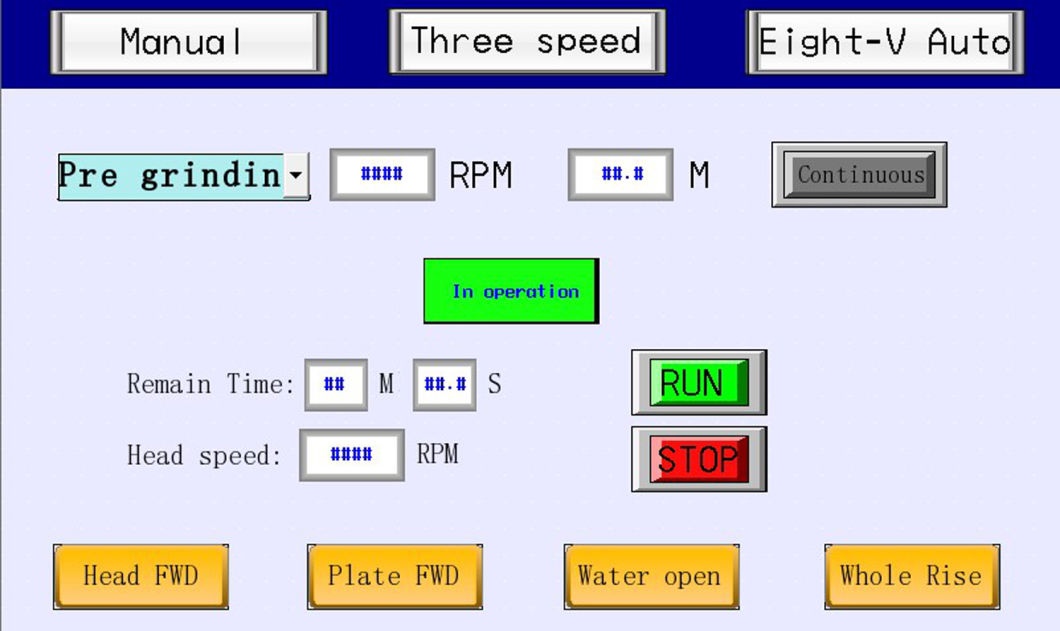

Support 8 segments programs:

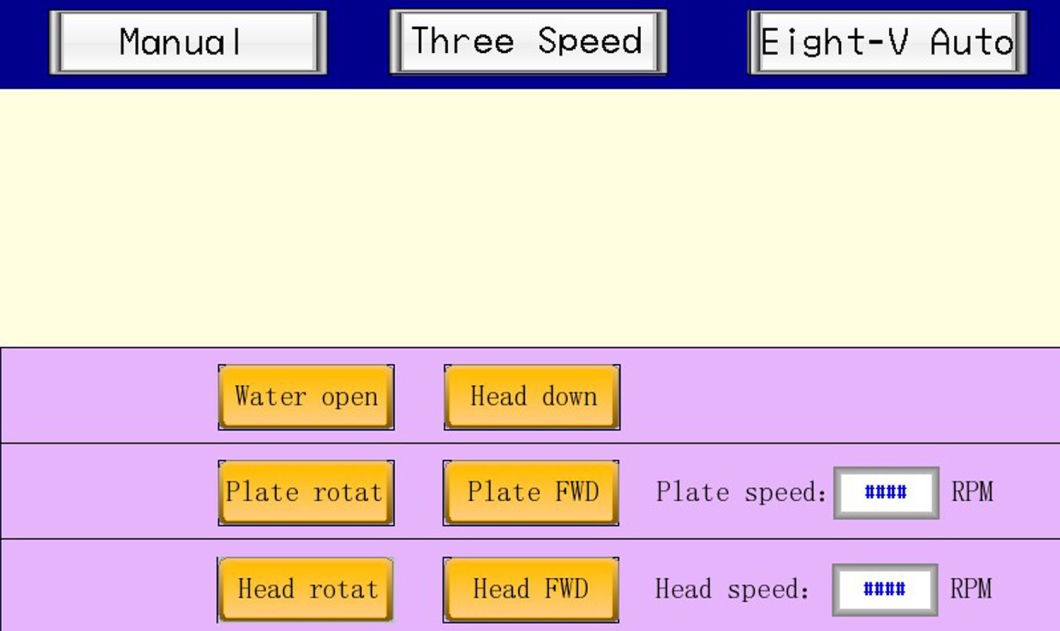

Setting Interface of user friendly color touch screen:

Product Feature:

1. Six pieces Φ30mm samples can be polished simultaneous

2. Single point pneumatic holding, no demo gripper

3. Multiple functions: one machine realizes the whole process of rough grinding, fine grinding, rough polishing and fine polishing of metallographic samples.

4. Single chip microcomputer control system, frequency converter speed control, the system is stable and reliable.

5. Grinding head with automatic / manual mode can be selected.

6. Three level constant speeds: customer can define three common speeds for pre-grinding, grinding and polishing

7. The automatic mode of grinding disc has eight sections of speed programming, which can set eight sections of speed and corresponding running time. Each section of speed can be automatically shut down at the corresponding time to facilitate users to replace sandpaper and polishing tissue.

8. Through the use of solenoid valve to control the water on and off, grinding disc under the automatic water spray cleaning device, can clean the inner wall of the sink.

9. Easily replace magnetic anti-stick disk, can complete all kinds of sample coarse, fine grinding and coarse, fine polishing processes, a plate is equivalent to N plates.

10. Beautiful outlook and good quality

Technical specification:

Model | GP-1000 |

Working disc diameter | φ254mm (option:φ230mm, φ203mm) With magnetic disk system |

Sample quantity | Standard 6 pieces of φ30 (or φ40 / φ50 three hole) |

Grinding disc speed | 100-1000 r/min; Support clockwise & anticlockwise rotate |

Three level constant speed | V1=300r/min V2=500r/min V3=800r/min; can set by needs at anytime |

Grinding head speed | 30-200r/min |

Sample holder | Standard φ30mm 6 pieces (Option: φ40-φ50mm 3 pieces,other size can be customized) |

Automatic mode | Can be programmed eight speed, running time and grinding wheel steering switch |

Working air source pressure range | ≥0.8MPa |

Sample pressure range | Suggestion:0.3-0.4MPa (recommend pressure >0.3MPa) |

Power supply | AC220V,50/60Hz |

Motor power | 0.75Kw |

Dimension | 700 x 730 x 350mm |

Weight | 74kg |

Standard accessories:

Item | Quantity | Item | Quantity |

Magnetic working plate(250mm) | 1piece | Anti-sticky disc(250mm) | 1peice |

Abrasive paper | 6 pieces | Polishing cloth | 2 pieces |

Waterproof ring | 1 piece | Water inlet pipe 8mm | 1 piece |

Water outlet pipe 25mm | 1 piece | Touch screen pen | 1 piece |

Anti-stick wheel | 1 piece | Magnetic wheel | 1 piece |

Power cord adapter (aviation plug connector) | 1 piece | Data cable (aviation plug) | 1 piece |

Rubber pad with filter | 1 piece | Triangle valve 4 | 1 piece |

Quick-connect coupling SNZ08-04 | 1 piece | Raw strip | 1 roll |

Hose clamp 21-44 | 1 piece | Filter mesh (# 60, double layer) | 4 pieces |

machine manual | 1 set | machine certification | 1 set |

Machine Guarantee card | 1 set | packing list | 1 set |

Main interface of 7'' Color touch screen:

Support 8 segments programs:

Setting Interface of user friendly color touch screen: