| Availability: | |

|---|---|

E-500A

EBP INSTRUMENTS

Shanghai, China

300 Sets Per Month

T/T in advance

1 set

Introduction:

50X-1000X E-500A Inverted metallurgical microscope is equipped excellent UIS optical system and modularization function design so that update system expediently and achieved polarization, dark field observation.

Compact and steady main frame body is embodiment for the shock resistance. The ideal ergonomic design is adopted in this unit and has easier operation and wider space. This is ideal optical instrument for micro observation in metallographic structure and surface morphology. It is suitable for research in metallography, mineralogy, precision engineering, etc.

Technical Parameter:

Model | E-500A |

Eyepiece | 10X wide field plan eyepiece and field of view number is Φ22mm, the eyepiece interface is Ф30mm |

Bright Field Objective | PL L5X/0.12 working distance: 9.70 mm PL L10X/0.25 working distance: 20.2 mm PL L20X/0.40 working distance: 8.80 mm PL L50X/0.70 working distance: 3.68 mm PL L100X/0.85 (dry) working distance: 0.40 mm |

Nosepiece | Quintuple / Five hole (Backward ball bearing inner locating) |

Eyepiece tube | Hinged binocular tube, with an observation angle of 45°, and a pupil distance of 53-75mm |

Focusing system | Coaxial coarse/fine focus, with tension adjustable and up stop minimum division of fine focusing is 2μm |

Stage | Mechanical stage overall size: 242mmX200mm and moving range : 30mmX30mm. Rotundity and rotatable stage size: maximal measurement is Ф130mm and minimal clear aperture is less Ф12mm |

Illumination | 6V 30W halogen and brightness enable control. Integrated field diaphragm, aperture diaphragm and puller type polarizer. Equipped with frosted glass and filters |

Polarizing set | Analyser can be rotatable and both polarizer and analyser can be move light path |

Filter | Blue, green, yellow |

Operation Environment | l Indoor l Altitude: 2000m Max. l Temperature: 5℃-40℃ (41℉-104℉) l Humidity: 80% for 31℃ (88℉) 70% for 34℃ (93℉) 60% for 37℃ (99℉) 50% for 40℃ (104℉) l Pollution: 2 (Refer to IEC664) |

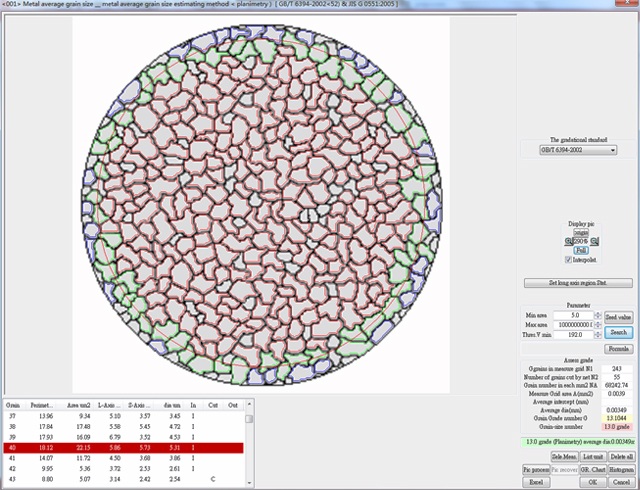

This software can be used with a variety of metallographic microscope to complete the metallographic image acquisition, processing, analysis, report generation and other functions; also have to view the library, geometric measurement, fixed-fold printing, image stitching, image contrast, confocal ), Three-dimensional light maps and other functions. Compared with the traditional manual method, the sample software for metallographic image analysis, with the following advantages:

save the traditional darkroom camera system, directly with a digital camera to take pictures, photos can be saved or printed.

can be compared on the computer map and standard query, do not read the standard books.

can be quickly and accurately automatically calculate the various types of microstructure of the perimeter, area, long axis, short axis, equivalent circle diameter,

Aspect ratio, area percentage and other geometric shape parameters, than the previous manual calculation method has greatly improved.

quantitative metallographic standards can be applied to automatically calculate the level, the level of results to allow human intervention.

can automatically generate the electronic document inspection report, the report can be saved as WORD, EXCEL, PDF and other documents.

The whole inspection process is complete on the computer, to achieve office paperless, greatly enhance the level of enterprise information.

Metallographic analysis:

The software includes eight major categories, more than 100 inspection standards (including GB, JB, QC / T, NJ, DL, YB, TB / T, ISO, ASTM, JIS, etc.), more than 600 metallographic image analysis module, The standards covered are:

commonly used: including grain size, non-metallic inclusions, decarburization layer, quantitative metallographic, phase area analysis.

cast iron: including ductile iron, gray cast iron, vermicular graphite cast iron analysis.

steel: including stainless steel, tool steel, all kinds of carbon steel, all kinds of alloy steel analysis.

Non-ferrous metals and alloys: including aluminum alloy, magnesium alloy, copper alloy, titanium alloy analysis.

vehicles and engines: all types of vehicles, gears, engine and accessories analysis.

power industry standards.

Other: There are powder metallurgy, metallography teaching.

ASTM, DIN, JIS and other foreign standards.

Introduction:

50X-1000X E-500A Inverted metallurgical microscope is equipped excellent UIS optical system and modularization function design so that update system expediently and achieved polarization, dark field observation.

Compact and steady main frame body is embodiment for the shock resistance. The ideal ergonomic design is adopted in this unit and has easier operation and wider space. This is ideal optical instrument for micro observation in metallographic structure and surface morphology. It is suitable for research in metallography, mineralogy, precision engineering, etc.

Technical Parameter:

Model | E-500A |

Eyepiece | 10X wide field plan eyepiece and field of view number is Φ22mm, the eyepiece interface is Ф30mm |

Bright Field Objective | PL L5X/0.12 working distance: 9.70 mm PL L10X/0.25 working distance: 20.2 mm PL L20X/0.40 working distance: 8.80 mm PL L50X/0.70 working distance: 3.68 mm PL L100X/0.85 (dry) working distance: 0.40 mm |

Nosepiece | Quintuple / Five hole (Backward ball bearing inner locating) |

Eyepiece tube | Hinged binocular tube, with an observation angle of 45°, and a pupil distance of 53-75mm |

Focusing system | Coaxial coarse/fine focus, with tension adjustable and up stop minimum division of fine focusing is 2μm |

Stage | Mechanical stage overall size: 242mmX200mm and moving range : 30mmX30mm. Rotundity and rotatable stage size: maximal measurement is Ф130mm and minimal clear aperture is less Ф12mm |

Illumination | 6V 30W halogen and brightness enable control. Integrated field diaphragm, aperture diaphragm and puller type polarizer. Equipped with frosted glass and filters |

Polarizing set | Analyser can be rotatable and both polarizer and analyser can be move light path |

Filter | Blue, green, yellow |

Operation Environment | l Indoor l Altitude: 2000m Max. l Temperature: 5℃-40℃ (41℉-104℉) l Humidity: 80% for 31℃ (88℉) 70% for 34℃ (93℉) 60% for 37℃ (99℉) 50% for 40℃ (104℉) l Pollution: 2 (Refer to IEC664) |

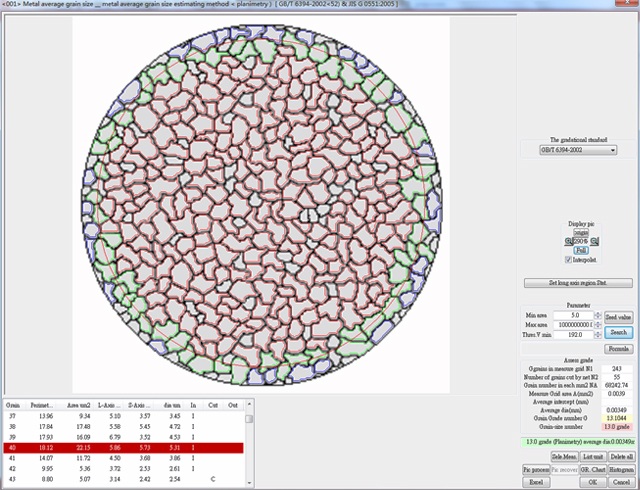

This software can be used with a variety of metallographic microscope to complete the metallographic image acquisition, processing, analysis, report generation and other functions; also have to view the library, geometric measurement, fixed-fold printing, image stitching, image contrast, confocal ), Three-dimensional light maps and other functions. Compared with the traditional manual method, the sample software for metallographic image analysis, with the following advantages:

save the traditional darkroom camera system, directly with a digital camera to take pictures, photos can be saved or printed.

can be compared on the computer map and standard query, do not read the standard books.

can be quickly and accurately automatically calculate the various types of microstructure of the perimeter, area, long axis, short axis, equivalent circle diameter,

Aspect ratio, area percentage and other geometric shape parameters, than the previous manual calculation method has greatly improved.

quantitative metallographic standards can be applied to automatically calculate the level, the level of results to allow human intervention.

can automatically generate the electronic document inspection report, the report can be saved as WORD, EXCEL, PDF and other documents.

The whole inspection process is complete on the computer, to achieve office paperless, greatly enhance the level of enterprise information.

Metallographic analysis:

The software includes eight major categories, more than 100 inspection standards (including GB, JB, QC / T, NJ, DL, YB, TB / T, ISO, ASTM, JIS, etc.), more than 600 metallographic image analysis module, The standards covered are:

commonly used: including grain size, non-metallic inclusions, decarburization layer, quantitative metallographic, phase area analysis.

cast iron: including ductile iron, gray cast iron, vermicular graphite cast iron analysis.

steel: including stainless steel, tool steel, all kinds of carbon steel, all kinds of alloy steel analysis.

Non-ferrous metals and alloys: including aluminum alloy, magnesium alloy, copper alloy, titanium alloy analysis.

vehicles and engines: all types of vehicles, gears, engine and accessories analysis.

power industry standards.

Other: There are powder metallurgy, metallography teaching.

ASTM, DIN, JIS and other foreign standards.