| Availability: | |

|---|---|

R-45NT

EBP INSTRUMENTS

Shanghai / Shenzhen / Ningbo

150 sets per month

TT in advance

1 set

Features:

Features:

1. With superficial Rockwell testing function.

2. Nose mounted indenter allows access to awkward to reach test points ( ring shape material, tubular material, etc). Minimum working diameter is 25mm.

3. Touch-screen interface, English language, all test data can show on screen directly.

4. Closed loop force application, load cell instead of dead weights, no need to install weights, working directly after connect with electric power.

5. Semi-automatic type, premier test force load by manual, then mian load force loading by motor (loading main force, dwell, unload automatically), greatly improved working efficienty.

6. Test force automatic correction, improve the accuracy of a force of magnitude

7. All Rockwell scale, test result / hardness value (high, medium and low hardness value) can be automatically calibrated on screen.

8. Operator can set up a password for the machine to protect setup parameters; Safely keep test informations and setted parameters.

9. Test data can export to U disk in EXCEL format, for long time keep and easy editing and processing.

10. Machine adopted modular design, easy maintenance.

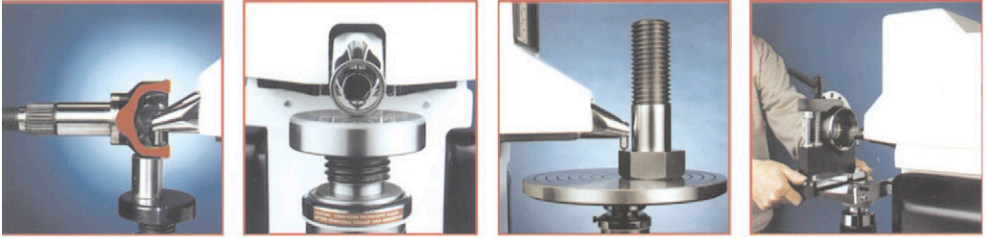

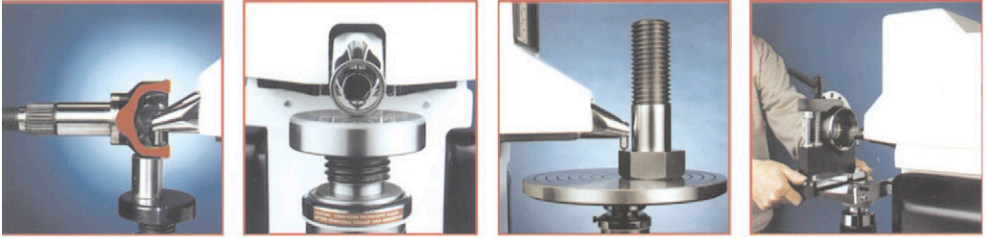

Dolphin Nose Indenter (Nose mounted indenter) allows access to awkward to reach test points:

1) Ring shape material

2) Tubular material

3) Screw corner

4) Bearing corner, etc.

Application Fields:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Technical Specifications:

Model Name | R-45NT |

Test force (error < 0.5%) | 15kgf (147.1N) 30kgf (294.2N) 45kgf (441.3N); Initial force: 3kgf (29.4N) |

Superficial Rockwell scale | 15N, 15T, 15W, 15X, 15Y, 30N, 30T, 30W, 30X, 30Y, 45N, 45T, 45W, 45X, 45Y |

Conversion scales | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

Superficial Rockwell test range | HR15N: 70-94, HR30N: 42-86, HR45N: 20-77 HR15T: 67-93, HR30T: 29-82, HR45T: 10-72 |

Dwell time | 0-99s |

Display of Hardness Value | Touch LCD screen |

Test accuracy | 0.1HR |

Executive standard | BSEN 6508, ISO 6508, ASTM E18, GB/T230 |

Data output | USB flash disk (Excel format) |

Power supply | AC220±5%, 50-60Hz |

Test space | Max. Height: 300mm; Throat depth: 250mm |

Machine size | 720*260*840mm |

Net weight | 80kg |

Standard Accessories:

Name | Quantity | Name | Quantity |

Diamond Rockwell indenter | 1 | Ø1.5875mm Ball indenter | 1 |

Hardness block ( HR15N, HR30N, HR30T) | 3 | Large, medium, V-type working table | 1 for each |

USB flash disk | 1 | Touch screen pen | 1 |

Fuse 2A | 2 | Horizontal adjustment screw | 4 |

Power cable | 1 | Product Certificate, warranty card, manual book | 1 for each |

The scales, indenters, test forces of the Rockwell hardness test and examples of application.

Scale | Indenter | Initial Test Force(N) | Total Test Force (N) | Examples of Applications |

HRA | Diamond Indenter | 98.07(10kg) | 588.4(60kg) | Hard metal and hard alloy |

HRD | 980.7(100kg) | Steel sheet, surface-quenched steel | ||

HRC | 1471(150kg) | Heat treated structural steel, tool steel | ||

HRF | Ball Indenter φ1.5875mm (1/16 inch) | 588.4(60kg) | Non-ferrous metals | |

HRB | 980.7(100kg) | Non-ferrous metals; soft metals | ||

HRG | 1471(150kg) | Pearlite iron, copper, nickel, zinc alloy | ||

HRH | Ball Indenter φ3.175mm (1/8 inch) | 588.4(60kg) | Annealed copper alloy | |

HRK | 1471(150kg) | Non-ferrous metals, hard plastics | ||

HRE | 980.7(100kg) | Aluminum and aluminum alloy | ||

HRL | Ball Indenter φ6.35mm (1/4 inch) | 588.4(60kg) | ||

HRM | 980.7(100kg) | |||

HRP | 1471(150kg) | |||

HRR | Ball Indenter φ12.7mm (1/2 inch) | 588.4(60kg) | ||

HRS | 980.7(100kg) | |||

HRV | 1471(150kg) |

Features:

Features:

1. With superficial Rockwell testing function.

2. Nose mounted indenter allows access to awkward to reach test points ( ring shape material, tubular material, etc). Minimum working diameter is 25mm.

3. Touch-screen interface, English language, all test data can show on screen directly.

4. Closed loop force application, load cell instead of dead weights, no need to install weights, working directly after connect with electric power.

5. Semi-automatic type, premier test force load by manual, then mian load force loading by motor (loading main force, dwell, unload automatically), greatly improved working efficienty.

6. Test force automatic correction, improve the accuracy of a force of magnitude

7. All Rockwell scale, test result / hardness value (high, medium and low hardness value) can be automatically calibrated on screen.

8. Operator can set up a password for the machine to protect setup parameters; Safely keep test informations and setted parameters.

9. Test data can export to U disk in EXCEL format, for long time keep and easy editing and processing.

10. Machine adopted modular design, easy maintenance.

Dolphin Nose Indenter (Nose mounted indenter) allows access to awkward to reach test points:

1) Ring shape material

2) Tubular material

3) Screw corner

4) Bearing corner, etc.

Application Fields:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Technical Specifications:

Model Name | R-45NT |

Test force (error < 0.5%) | 15kgf (147.1N) 30kgf (294.2N) 45kgf (441.3N); Initial force: 3kgf (29.4N) |

Superficial Rockwell scale | 15N, 15T, 15W, 15X, 15Y, 30N, 30T, 30W, 30X, 30Y, 45N, 45T, 45W, 45X, 45Y |

Conversion scales | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

Superficial Rockwell test range | HR15N: 70-94, HR30N: 42-86, HR45N: 20-77 HR15T: 67-93, HR30T: 29-82, HR45T: 10-72 |

Dwell time | 0-99s |

Display of Hardness Value | Touch LCD screen |

Test accuracy | 0.1HR |

Executive standard | BSEN 6508, ISO 6508, ASTM E18, GB/T230 |

Data output | USB flash disk (Excel format) |

Power supply | AC220±5%, 50-60Hz |

Test space | Max. Height: 300mm; Throat depth: 250mm |

Machine size | 720*260*840mm |

Net weight | 80kg |

Standard Accessories:

Name | Quantity | Name | Quantity |

Diamond Rockwell indenter | 1 | Ø1.5875mm Ball indenter | 1 |

Hardness block ( HR15N, HR30N, HR30T) | 3 | Large, medium, V-type working table | 1 for each |

USB flash disk | 1 | Touch screen pen | 1 |

Fuse 2A | 2 | Horizontal adjustment screw | 4 |

Power cable | 1 | Product Certificate, warranty card, manual book | 1 for each |

The scales, indenters, test forces of the Rockwell hardness test and examples of application.

Scale | Indenter | Initial Test Force(N) | Total Test Force (N) | Examples of Applications |

HRA | Diamond Indenter | 98.07(10kg) | 588.4(60kg) | Hard metal and hard alloy |

HRD | 980.7(100kg) | Steel sheet, surface-quenched steel | ||

HRC | 1471(150kg) | Heat treated structural steel, tool steel | ||

HRF | Ball Indenter φ1.5875mm (1/16 inch) | 588.4(60kg) | Non-ferrous metals | |

HRB | 980.7(100kg) | Non-ferrous metals; soft metals | ||

HRG | 1471(150kg) | Pearlite iron, copper, nickel, zinc alloy | ||

HRH | Ball Indenter φ3.175mm (1/8 inch) | 588.4(60kg) | Annealed copper alloy | |

HRK | 1471(150kg) | Non-ferrous metals, hard plastics | ||

HRE | 980.7(100kg) | Aluminum and aluminum alloy | ||

HRL | Ball Indenter φ6.35mm (1/4 inch) | 588.4(60kg) | ||

HRM | 980.7(100kg) | |||

HRP | 1471(150kg) | |||

HRR | Ball Indenter φ12.7mm (1/2 inch) | 588.4(60kg) | ||

HRS | 980.7(100kg) | |||

HRV | 1471(150kg) |